private label Shrinkage Testing|fabric shrinkage chart : discounter By conducting a shrinkage test using standard methods like JIS L1909, ISO6330/5077, or FZ/T70009, you can accurately predict how much your fabric will shrink after washing or drying. This information is essential for . web9 de abr. de 2023 · Nesse vídeo passei as melhores combinações de habilidades para usar no Free Fire dependendo de qual seja a sua função. Suporte, Rush, 2 Rush e Granadeiro.🔵 .

{plog:ftitle_list}

15 de mar. de 2023 · AetherSX2 is a emulator of the PS Two console for the Android platform. You can play games which you have dumped from disc on your portable device. A BIOS image **is required** to play games and is not optional.

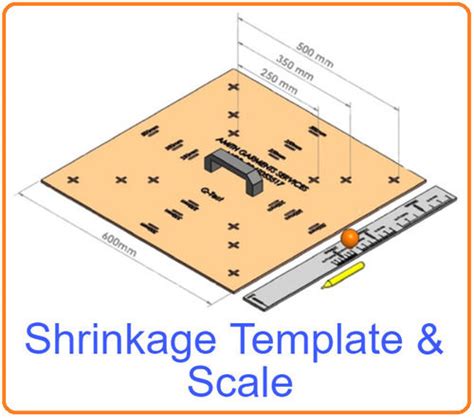

How to do a shrinkage test on fabric: Draw a 20"x 20" square parallel to selvage on a yard of fabric. Selvage to selvage. Make sure to draw with a permanent felt tip marker for light colors or metallic gel pen for dark colors . Wash the fabric . When fabrics are expected to undergo repeated laundering, evaluating the shrinkage or growth is key in acceptance testing. Using the Skew & Shrinkage Template, lab technicians can perform AATCC TM135, Test . Using the Skew & Shrinkage Template, lab technicians can perform AATCC TM135, Test Method for Dimensional Changes of Fabrics after Home Laundering to measure . The fabric shrinkage rate is a measurement that quantifies the reduction in the size of fabric after specific treatments or conditions. It is typically expressed as a percentage of the .

By conducting a shrinkage test using standard methods like JIS L1909, ISO6330/5077, or FZ/T70009, you can accurately predict how much your fabric will shrink after washing or drying. This information is essential for . AATCC testing standards cover diverse aspects of apparel quality control like colorfastness, shrinkage, fabric and seam quality, aiming to ensure garments meet the requisite performance and safety standards. ISO 6330 is an international standard determining the percentage of shrinkage a textile product will experience after home laundry. This method includes specific requirements and conditions related to humidity, . The dimensional stability of a fabric is a measure of the extent to which it keeps its original dimensions to its manufacture. Shrinkage is a problem that hampers the dimensional stability of a fabric. A recent survey of .

Efficient quality control is made easy with Lenzing Instruments Thermal Shrinkage Tester TST 1, which tests one sample with a width of up to 50 mm for percent shrinkage or shrinkage force .Film Shrinkage test, known as linear thermal shrink test or free shrink test, is used for analyzing the effect of temperature on heatshrinkable films made from polyethylene, ethylene copolymers and their mixtures. Basically, shrinking . The shrinkage can be completed in a non-high temperature environment so that the heat-shrinkable label can be packaged on the outside of the container. After the horizontal shrinkage of the label is completed, the height of the label is hardly shortened in the vertical direction due to the vertical shrinkage. OPS hardly generates crystal points. When fabrics are expected to undergo repeated laundering, evaluating the shrinkage or growth is key in acceptance testing. Using the Skew & Shrinkage Template, lab technicians can perform AATCC TM135, Test .

Learn how to prevent shrinkage problems in your garments by following five simple steps. Find out how to choose, test, pre-shrink, cut, sew, press, and finish your fabric. For example, select retailers are testing private label–only stores since it is a working supposition that national brands are more desirable for resale by organized retail crime groups. Shifting a high-shrink store to private label only may in fact reduce shrink in that location, but it also may drive paying customers to nearby competitors .

Label Application & Encoding; Shrink Wrap & Induction Sealing; Product Testing; POP Display Development . and so much more! Our staff of scientists, formulators, certified aromatherapists, estheticians, graphic designers and private labeling experts can help you take and idea and turn it into reality. . Hi there, thanks for reaching out. A .Enjoy vibrant and consistent colors and fine-point details on scuff-resistant materials to make your products stand out for good. From bottles, mock-ups or CAD drawings, we’ll work with you through product development and testing to create the shrink sleeve packaging that makes you stand out —and win— on the shelves.Shrink wrap labels offer a variety of benefits, including the way they allow you to tell your brand’s story through labeling. When you shrink labels onto your products, you increase the label’s space for branding and information by 150%. With that increase in real estate, you can provide as much information as your customers need. The extra space gives you the chance to explain .Australian Private Label has comprehensive testing capabilities to support your business in launching and scaling products into market. From Preservative Efficacy Testing for shelf life to Stability Testing. More. Custom Samples Aluminium Tube Filling eCommerce Shipping .

Our team will help you make full use of your shrink label space. 800.537.9429. . Private Label Capabilities. . department was able to provide accurate die-lines from a sample bottle in a timely manner and Century delivered seamed test labels to our factory in Hong Kong on short notice. The test run was successful and Century was extremely .Measuring the Shrinkage of Fabrics & Garments. Many methods exist for measuring the shrinkage of cotton fabrics and garments. The most reliable methods use a system that properly prepares the sample for the test, agitates the goods without tensions or restrictions on the fabric, and measures the results accurately.Once your design is ready, you’ll need to find the right shrink sleeve label company. At Blue Label, we have the experts and equipment to guide you through the shrink sleeve printing and converting process. Our hands-on team will work with you to identify opportunities, such as testing barcodes that may be skewed from the shrinking process.

Today, most shrink sleeves are made of plastic polymers, such as: PET, PETG, OPS, PVC, PLA and more. Each film type will exhibit its own unique shrink properties and determining which offering is best for a project can be weighed by many factors. Resource Label Group can advise you on the best film selection in pursuit of your project goals. Shrink sleeving is all about using the right application and shrink tunnel technology, but it is important to realize there is no one-size-fits-all solution in the successful application and shrinking of shrink sleeve labels. Keep an open mind, and if you run into issues keep our shrink sleeve troubleshooting guide handy to point you in the . You’ll want to test the private label products yourself before making a big order and trying to sell them. Many private label goods look incredible online. You may be sold once you talk to the manufacturer, whose .

the residual shrinkage proper-ties of the material, depending on entered test specifications. Results: Results of the TST 1 measu-rement are not limited to nu-merical data of the registered length difference or shrinkage force, but the shrinkage beha-viour of the heated material is displayed graphically at each point of the test duration as wellPRIVATE LABEL SOLUTIONS. Launch, extend or revise your private label concept with Beverage Testing Institute. BTI INTEGRITY. Our priority is getting the right liquid for our clients. BTI’s independence means you get access to the largest pool of supplier candidates. . Every test is custom-designed to your goals so you can make decisions . Step-2: Preparation of the specimen: The general procedures for preparing and marking out of samples are given in the British Standard. For critical work the recommended sample size is 500mm X 500mm and for routine work a minimum sample size of 300mm X 300mm is considered sufficient.The samples are marked with three sets of marks in each . Private Label Manufacturing. Safety News; Contact; Flame Resistant NFPA2112 NFPA 2112 Standard Overview. . NFPA 2112, par 8.4, Heat and Thermal Shrinkage Resistance Test. This test is essentially two tests in one. Three large squares of fabric are cut, measured and marked, then placed in a 260°C oven for 5 minutes to determine whether they .

High Frequency wood moisture meter suppliers

Label Testing Equipment. When manufacturing qualified labels, manufactures should have several considerations in designing and processing: . C631H Thermal Shrinkage Tester is designed and developed in accordance with ISO 14616 , for determination of shrinking force, contracting force and shrinkage ratio of heatshrinkable films. .Basically, there are three test methods for film shrinkage testing: Oil Bath Method (ASTM D2732), Drying Oven Method and Air Heating Method (ISO 14616). Currently, Labthink has two models of shrinkage testers based on Oil Bath Method (RSY-R2) .ASTM C157 Un-restrained (free) Shrinkage Test • 1” to 4” rectangular prism sizes possible (depends on max aggregate size) – 1” prism most common for mortar – 3” prism for 1” coarse aggregate – 4” prism for 2” coarse aggregate • Standard recommends moist curing for 28 .

Explore quizzes and practice tests created by teachers and students or create one from your course material. . by merchandise being misplaced or damaged, or by poor bookkeeping. Also called shrinkage. . A branding strategy that offers the consumer a private label at a comparable manufacturer-brand quality, usually with a modest price . Test Methods. The Smartshrink Rate Tester utilizes a specific test method to accurately measure fabric shrinkage. It applies controlled tension and heat to the fabric sample while recording its dimensional changes. Test Procedures. To conduct a fabric shrinkage test using the Smartshrink Rate Tester, the following procedures are typically followed:

When fabrics are expected to undergo repeated laundering, evaluating the shrinkage or growth is key in acceptance testing. Using the Skew & Shrinkage Template, lab technicians can perform AATCC TM135, Test Method for Dimensional Changes of Fabrics after Home Laundering to measure shrinkage of fabrics in length and width directions.Shrink curves affect how well a shrink sleeve conforms to the container, whether it fits snugly without distortion of the label graphics, even the final label height. Below we explain shrink curves so you can ensure a perfect end-product when using shrink sleeve labeling. Primer on How Shrink Sleeve Labeling WorksThis test method is used to provide documentation that a given concrete mixture will meet a specified shrinkage limit. A typical concrete mixture for slab-on-ground applications will have a 28-day drying shrinkage in the range of 0.050 to 0.060 percent. Drying shrinkage limits in project specifications typically range from 0.035

shrinkage testing template

shrinkage testing

shrinkage tester for fabric

Overview. Sports enthusiasts will find plenty to cheer about at UBC. There are more than a dozen high-performing Thunderbird varsity teams, including basketball, volleyball, .

private label Shrinkage Testing|fabric shrinkage chart